Protecting Superyachts

CORROSION’s revolutionary cooler and anti-fouling solution designed to meet the unique needs of Superyachts.

CORROSION’s revolutionary cooler and anti-fouling solution designed to meet the unique needs of Superyachts.

In an exclusive partnership with high-end partners including Philips, CORROSION has developed a non-chemical cooling and anti-fouling solution to meet the specific requirements of superyachts. The cooling system, which features an integrated UV-C MGPS system, is both a highly efficient and environmentally friendly means to prevent marine growth thanks to the use of

UV-C light.

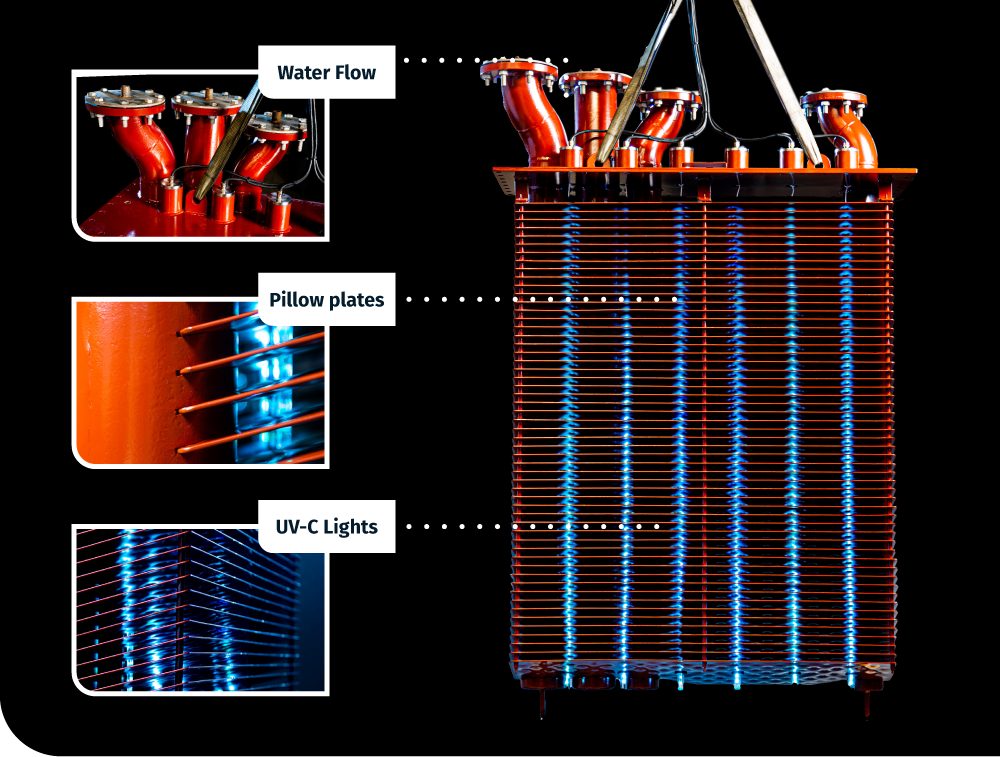

In an exclusive partnership with high-end partners including Philips, CORROSION has developed a non-chemical cooling and anti-fouling solution to meet the specific requirements of superyachts. The cooling system, which features an integrated UV-C MGPS system, is both a highly efficient and environmentally friendly means to prevent marine growth thanks to the use of UV-C light.

Gamechanger

CORROSION first began researching the use of UV light as a marine growth protection mechanism for traditional box coolers in 2017. As these tests revealed that such box coolers were not suitable for UV-C light protection, our research and technical teams started developing of a revolutionary new type of cooler.

The resulting solution, has been a real gamechanger, combining two existing and proven technologies into one product: the UV-C technique, patented by Philips, to prevent fouling, and ‘pillow plates’ to provide cooling.

Benefits

Applications

24/7 protection for superyachts

Environmentally friendly

Replacing lamps without dry docking

Retrofit to existing superyachts

AC sets

Generator sets

Main engines

Auxilary

Benefits

24/7 protection for superyachts

Environmentally friendly

Replacing lamps without dry docking

Retrofit to existing superyachts

Applications

AC sets

Generator sets

Main engines

Auxilary

UV-C Cooler

SUPERYACHT

UV-C Cooler

SUPERYACHT

A sustainable solution

Pillow plate UV-C Cooler

The UV-C pillow plate cooler is designed to withstand the rough conditions that superyachts experience at sea. The coolers are installed in the sea chests with an in and outlet grid. When in operation, seawater enters through the inlet grid and passes through the pillow plates (including when moored).

Cooling takes place here, with the heated seawater exiting the sea chest through the outlet grids. Sea water that is heated by the pillow plates causes a natural convection, ensuring that cooling is guaranteed. This heat transfer is achieved by a controlled flow of cooling liquid through the pillow shaped plates. The heat transfer of a pillow plate is significantly more efficient than that of a tube cooler due to its shape. This so-called pillow plate technique is proven technology that has been used for decades in other sectors.

Team UV-C

Location: Netherlands

CORROSION has been in the business of protecting vessels, offshore wind farms and onshore applications since 1993. From our humble beginnings in the small town of Moerkapelle in the Netherlands, we have grown into an internationally recognized leader in creative, sustainable, state-of-the-art solutions in corrosion and cathodic protection.

Henk

van der Lip

Downloads

Team UV-C

Location: Netherlands

Henk

van der Lip

Bas

Wessels

CORROSION has been in the business of protecting vessels, offshore wind farms and onshore applications since 1993. From our humble beginnings in the small town of Moerkapelle in the Netherlands, we have grown into an internationally recognized leader in creative, sustainable, state-of-the-art solutions in corrosion and cathodic protection.